LiFePo4 battery pack

LiFePo4 battery pack main be used for kinds of electric vehicles or energy storage system. These battery pack generally high capacity and high power, so the technology of assembly becoming very critical of battery pack service life.

The quality of lifepo4 battery pack is determined by its internal structure and BMS.

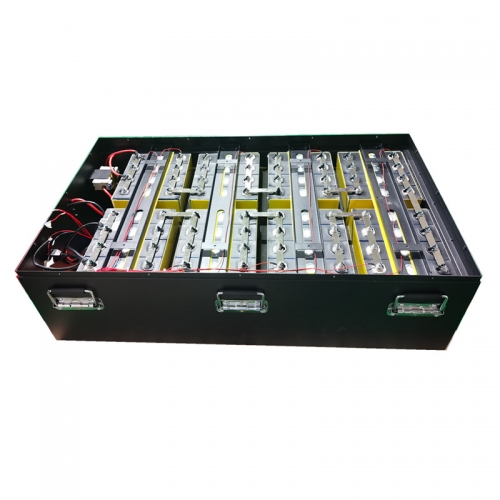

The factors we need consider for internal structure design:

1.Stability, the stability of cells and battery pack in enclosure is the foundation of one high power LiFePo4 battery pack, for one moving battery pack, any parts loosening will be ruinous. We need apply for kinds of holder to fix cells and frame to fix battery in the enclosure, one good designed enclose is necessary.

2.Insulation, when assemble one lifepo4 battery pack, we need consider of the insulation of each cell and cells with enclose if it is metal material. Battery pack Short-circuit is very dangerous. And shorten lifepo4 battery service life if no good insulation.

3.Heat dissipation, When design lifepo4 battery pack, we need leave enough space for cooling, specially on the top of positive and negative, over-heat will shorten battery pack life and even caught fire, that is not we would like to see.

4.Optimize connection schemes, better connection schemes will reduce the current lose, reduce the possibility of short-circuit, reduce virtual welding, make battery pack work stable in a long time.

The capacity of BMS research and development also very important for high power LiFePo4 battery pack, It not only involves in many series connection and high charge/discharge current, cell balances and battery protection, but also involves in compatible of communication protocols, these complicated thing, The quality of BMS is key point of one battery pack.

-

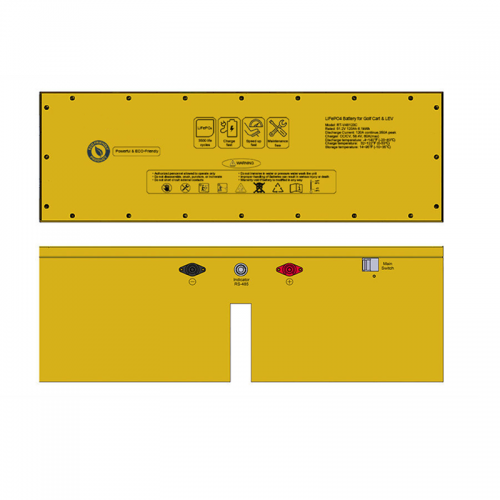

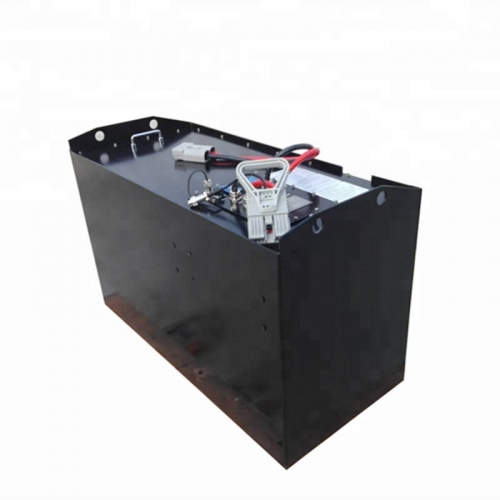

76.8V 72V 100AH Lifepo4 Batteries For Golf C...

-

25.6V 920Ah Lifepo4 Battery Pack for Truck...

-

72V 500Ah lifepo4 rechargeable battery pack...

-

48V 302Ah Solar Storage Battery For Home Use...

-

24v 300ah EV Lithium Ion Battery...

-

24 volt lithium battery 80ah 24v lifepo4 batteries...

-

12V 150Ah lifepo4 battery for solar energy system...

-

Golf cart lithium battery 72V 200Ah LiFePO4 b...

-

Golf cart lithium battery 36V 120Ah LiFePO4 b...

-

Golf cart lithium battery 48V 120Ah LiFePO4 b...

-

LiFePO4 Pack 51.2V 400Ah Lithium Battery...

-

16640W 80V 200Ah EV Lithium Ion Battery...